A "Specification" is a set of numerical limits and rules against

which entered data are checked to provide an indication of the "quality"

of entered data. Two methodologies are available to check data against a Specification:

Spec Limit Checking is conducted at the Data Item level by comparing entered

data to a set of Specification Limits, each of which indicates a "Spec

Condition". When the data value falls with a Specification Limit, the corresponding

Spec Condition is reported.

| Data

Entry

|

|

Items

Evaluated During Spec Limit Checking

|

| Sample

|

Data Set

|

Parameter

|

Data Value

|

|

Specification

Limit

|

Spec Condition

when Data Value is withing Specification Limit

|

| Sample-001 |

Metals |

Au |

7.2 |

|

Au < 10 |

Out of Spec |

| |

|

Al |

41.4 |

|

Al > 30 |

Out of Spec |

| |

|

Ni |

12.6 |

|

10 ≤ Ni ≤ 15 |

Warning |

| |

|

Fe |

27.9 |

|

30 ≥ Fe > 25 |

Warning |

| |

|

Pt |

19.5 |

|

15 ≤ Pt ≤ 25 |

In Spec |

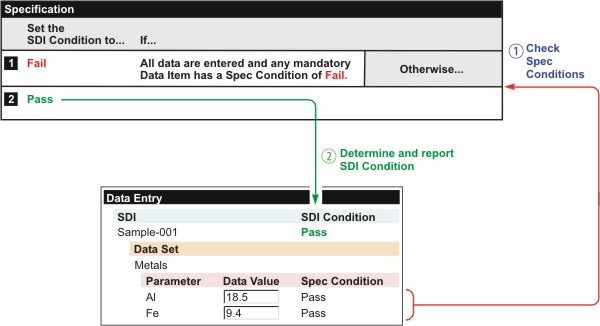

Spec SDI Checking begins by performing Spec Limit Checking as shown above.

Next, all Spec Conditions generated for the SDI are used to analyze one or more

Specification Rules. The Specification Rules determine the "SDI Condition",

which indicates the quality of all data entered for the SDI.

|

|

|

|

Spec Limit Checking Process

|

|

|

|

|

|

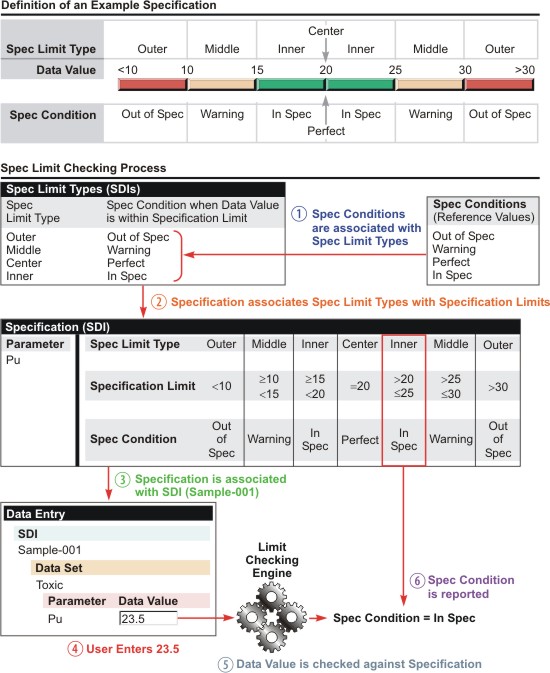

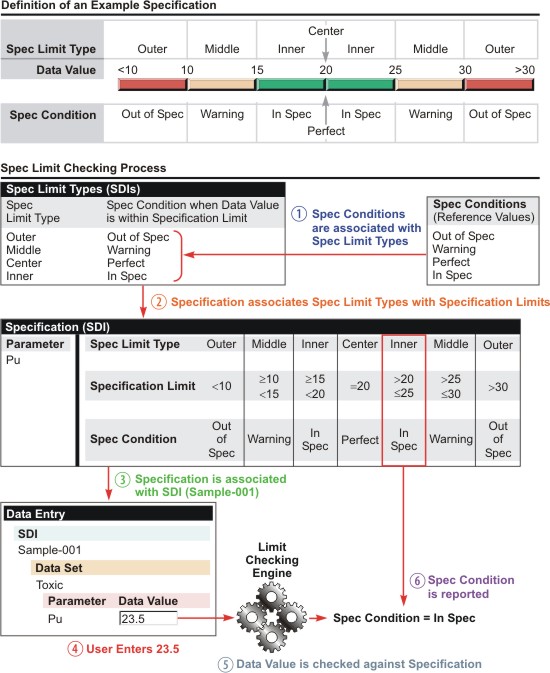

This example shows how Spec Limit Checking is conducted. At the Data Item level,

entered data are compared to the numerical Specification Limits. When entered

data falls within these limits, the "Specification Limit Type" defines

a "Spec Condition", which is reported to indicate where the data falls

(such as "Out of Spec" or "In Spec").

| 1.

|

Spec Conditions are associated with Spec Limit Types:

| • | The "Spec Condition" is a Reference Type used as a label

to indicate the quality of an entered data value. A single Spec Condition

is reported for each entered data value. | | • | The "Spec Limit Type" is an SDI used to determine how

the Spec Condition is reported during Data Entry (also see Note 1). |

|

| 2.

|

In the Specification, Spec Limit Types are associated with Specification

Limits:

| • | The "Specification" is an SDI that defines Specification

Limits and associates Spec Limit Types with Specification Limits. | | • | The "Specification Limit" defines a range of values against

which entered data are checked (also see Note 1). |

|

| 3.

|

The Specification is associated with the SDI. |

| 4.

|

Data are entered. |

| 5.

|

The data value is checked against the Specification. |

| 6.

|

The Spec Condition is reported. |

| Note 1: |

Limit Type SDCs are also used to define Parameter Limits.

When you add a Limit Type SDI, the Limit Type Maintenance Page offers a

choice of whether you want to apply the Limit Type to Parameters or Specifications.

To distinguish from Parameter Limit Types, this documentation uses the term

"Spec Limit Type" to describe Limit Types that define Specifications.

In the illustration above, the "Outer" Spec Limit Type identifies

a Spec Condition of "Out of Spe"c when a Data Value falls within

a Specification Limit. |

| Note 2: |

In the example above, the Spec Limit Type "Outer"

will indicate a Spec Condition of "Out of Spec" when the Data

Value is less than 10 or greater than 30. |

To summarize, here is what you must do prior to entering data for the SDI:

| a. |

Enable the Allow Specifications option for the SDC relevant to the SDI

for which you will enter data. |

| b. |

Add Spec Conditions. |

| c. |

Add Spec Limit Types (Limit Type SDIs for use in Specifications rather

than Parameter Limits).

Associate a Spec Condition with each Spec Limit Type. |

| d. |

Add a Specification SDI. In the Specification Maintenance Page:

| 1. | For each Parameter you want to check, associate each Specification

Limit with a Spec Limit Type. | | 2. | Enter the Specification Limits. After you have entered the

limits, you can view or hide some of the limit information displayed

by the Specification Maintenance Page by re-entering the Limit Type

Maintenance Page and exercising these display options. |

|

| e. |

Add the Specification (and Data Set containing the relevant Parameter)

to the SDI for which you will enter data. |

|

|

|

|

Spec SDI Checking Process

|

|

|

|

|

|

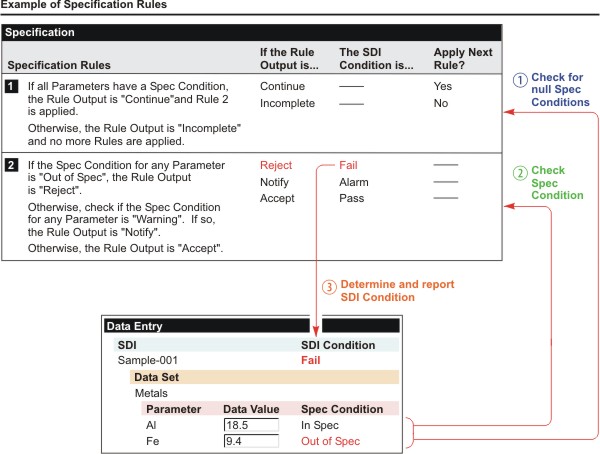

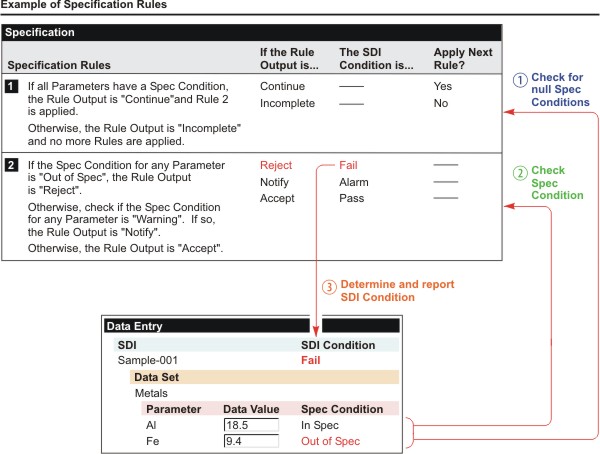

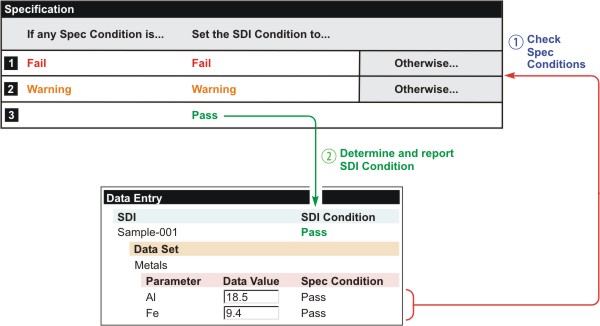

After the Spec Limit Checking process has determined a Spec Condition for each

Parameter, the check can be further extended by applying "Specification

Rules". These are conditional statements that use the Spec Conditions of

individual Parameters to determine an "SDI Condition", thus providing

an indication of all data entered for an SDI.

There are currently two types of engines that process Specification Rules:

| |

Rules Engine

|

Usage

|

|

|

Expression-Based |

Expression-Based Rules are no longer supported. This document describes

them only to provide a reference for users of LabVantage 5.2 and earlier

who must transition from LVX/Jaguar. |

|

|

Banded

Structured |

These rules work with any supported Application Server. |

As an example, consider entering a Data Value for each of two Parameters (Al

and Fe). Both Parameters belong to the Metals Parameter List, a single

instance (Data Set) of which is assigned to SDI_001. You want to determine an SDI

Condition to get an indication of all data for the SDI.

The illustration above shows how the entire process works. The table

below shows how you could define these Specification Rules under the Rules tab

of the Specification Maintenance Page.

| Rule |

Specification Rule Syntax and Meaning

|

Rule Output |

SDI Condition1 |

Stop |

| 1 |

if( ConditionsComplete(), "Continue", "Incomplete")

If all Parameters have a Spec Condition, the Rule Output is "Continue"

and Rule 2 is applied. Otherwise, the Rule Output is "Incomplete"

and no more Rules are applied. |

Continue |

None |

No |

| Incomplete |

None |

Yes |

| 2 |

if( ConditionExists( "Out of Spec" ), "Reject",

if( ConditionExists( "Warning" ), "Notify", "Accept"))

If the Spec Condition for any Parameter is "Out of Spec", the Rule Output

is "Reject". Otherwise, check if the Spec Condition for any Parameter

is "Warning"; if so, the Rule Output is "Notify". Otherwise, the

Rule Output is "Accept". |

Reject |

Fail |

No |

| Notify |

Alarm |

No |

| Accept |

Pass |

No |

1 The Specification Maintenance Page uses the term

Spec Condition to refer to the SDI Condition. You define SDI Conditions

the same way you define Spec Conditions, i.e., they are Reference Values you

define in the Spec Condition Reference Type.

During execution:

| • |

Rules are applied in the order listed. |

| • |

Each Rule returns a Rule Output that you define within the Rule. |

| • |

For each Rule, the Rule Output determines the SDI Condition reported. |

The above example assesses individual Spec Conditions for each Parameter as

follows:

| 1. |

Rule 1 determines if all Parameters have a Spec Condition. Spec

SDI Checking requires that all Parameters being checked have an associated

Spec Condition. Absence of a Spec Condition generally indicates that

data have not been entered for that Parameter. |

| |

a. |

If all Parameters have a Spec Condition, Rule 1 returns a Rule Output

of Continue. Since this Rule Output serves only to continue the checking

process, a Rule Output of Continue does not generate an SDI Condition.

Since the Stop option is disabled, the process continues and applies Rule

2. |

| |

b. |

If any Parameter does not have a Spec Condition, Rule 1 returns a Rule

Output of Incomplete. Since no Spec Conditions have been checked,

a Rule Output of Incomplete does not generate an SDI Condition. Since

the Stop option is enabled, no further Rules are applied. |

| 2. |

Rule 2 determines if the Spec Condition for any Parameter is Out of Spec

or Warning. |

| |

a. |

If a Spec Condition is Out of Spec, Rule 2 returns a Rule Output of Reject.

A Rule Output of Reject generates an SDI Condition of Fail. |

| |

b. |

If a Spec Condition is Warning, Rule 2 returns a Rule Output of Notify.

A Rule Output of Notify generates an SDI Condition of Alarm. |

| |

c. |

If no Spec Condition is Out of Spec or Warning, Rule 2 returns a Rule

Output of Accept. A Rule Output of Accept generates an SDI Condition

of Pass. |

As an example, suppose you set your Specification Limits to indicate the following

Spec Conditions:

| Spec Conditions: |

In Spec 15 <= x <= 25 |

|

Warning 5 < x < 15 |

|

Out of Spec 0 <= x <=

5 |

When you enter data, and as you change it, the two Rules in the previous

example should yield the following

results:

| Parameter |

Data Value |

Spec Condition |

Rule Output |

SDI Condition |

| Al |

18 |

In Spec |

Rule 1: Incomplete

Rule 2: (none) |

(none) |

| Fe |

|

|

| Fe |

3 |

Out of Spec |

Rule 1: Continue

Rule 2: Reject |

Fail |

| Fe |

10 |

Warning |

Rule 1: Continue

Rule 2: Notify |

Alarm |

| Al |

20 |

In Spec |

Rule 1: Continue

Rule 2: Accept |

Pass |

Specification Rules do nothing more and nothing less than you tell them.

You must account for all possibilities that can occur during a Data Entry session.

In general, check for the following occurrences in the order specified:

| 1. |

Check for Spec Conditions

Parameters without Spec Conditions indicate that Spec Limit Checking was

not conducted, usually because data have not yet been entered. Erroneous

results are returned if you do not check for missing Spec Conditions.

In the example above, Rule 1 performs this check. |

| 1. |

Check for Spec Conditions from Worst to Best

Begin Check for worst-case Spec Conditions, working your way toward best

(such as Rule 2 in the example above). |

After these rudimentary checks, you can perform more specific or advanced checking

if required.

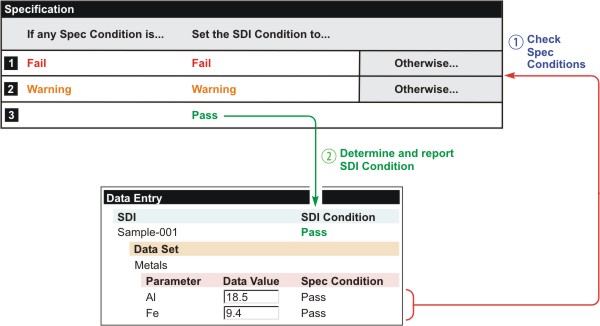

Banded

and Structured Rules

|

|

These are easier to use than Expression-Based Rules.

Recall from the previous discussions that, when using Specification Rules:

| • |

Spec Limit Checking is conducted first. This compares entered data to

a set of Specification Limits, each of which indicates a Spec Condition.

When the data value falls with a Specification Limit, the corresponding

Spec Condition is reported. |

| • |

Spec SDI Checking begins by performing Spec Limit Checking. Then, all

Spec Conditions generated for the SDI are used to analyze one or more Specification

Rules. The Specification Rules determine the SDI Condition, which

indicates the quality of all data entered for the SDI. |

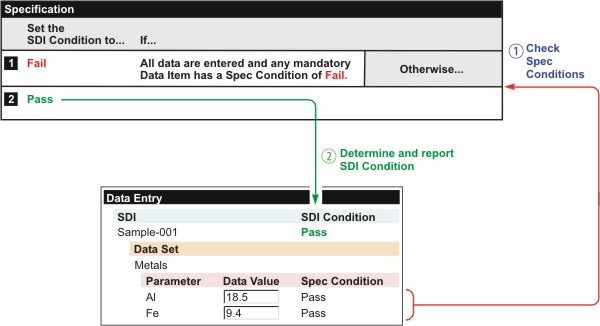

Banded Rules cover the most basic case. Multiple "bands" can be specified,

with the final band being the default condition. Here's an example:

Structured Rules let you create multiple rules, each defining a series of conditions

according to fixed grammar. The Rules Engine processes each rule individually,

stopping after it processes a rule that returns true. Example:

Unlike Banded Rules, a default condition is not necessary. However, one can

be specified as shown in the above example.

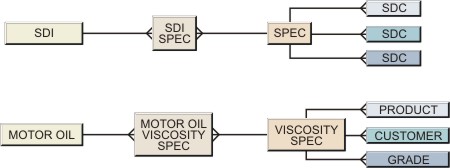

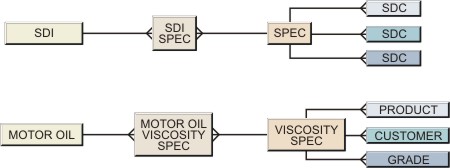

Linking Specifications to other SDCs

|

|

The Specification SDC (SpecSDC) is a System SDC, thereby letting you add

columns and link it to any other SDC. You can relate a Specification

to SDIs by creating an SDC Link from a Specification column to the relevant

SDC.

The two models below show the relationship. The first generic model shows

how SDIs "own" a Specification. The second model is an example

of how Motor Oil can be checked against the Viscosity Spec, which has the

columns Product, Customer, and Grade. Using three SDC Links, the Viscosity

Spec applies to SDIs in the SDCs Product, Customer, and Grade.