Introduction |

|

|

QC Rules let you define the statistical process control method to apply when evaluating QC Batches. Define the method using Western Electric Company (WECO) Rules and the Westgard Multi-Rules Procedure.

A QC Rule is a directive used during the evaluation of the QC Samples of a QCBatch. These directives can determine when a QCBatch is trending out of control and show when an individual datapoint is outside of a limit range or exhibits a trending tendency.

When the QC Rule defined here is included on a QC Method, these rules are applied to the QC Batch Sample data.

Add a New QC Rule |

|

|

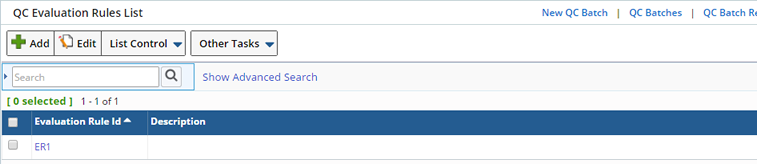

To create a new QC Rule navigate to the AQC → QC Rules tramstop. The QC Evaluation Rules List page displays.

|

|

Click "Add" to add a new rule or select an existing rule and click "Edit" to make changes.

Identify the Rule |

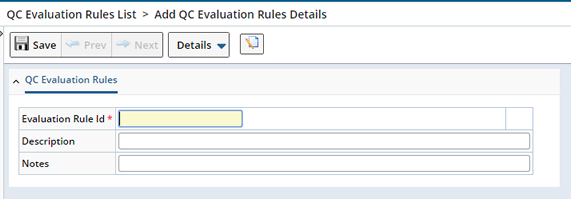

Identify, and provide additional information about the rule.

|

|

| Field | Description |

| Evaluation Rule Id | Identifier of the QC Rule. |

| Description | Textual description. |

| Notes | Additional information about the QC Method. |

Define the Rules |

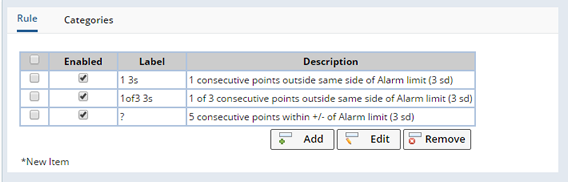

After saving, the Rule detail displays (shown below with rules already added).

|

|

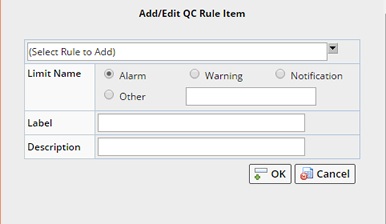

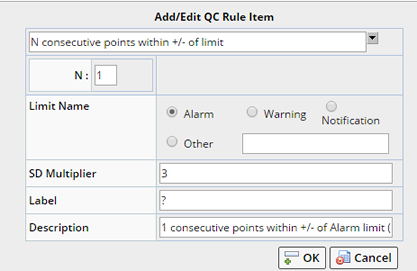

To define Rules and their criteria, click "Add".