|

Product Variant Rules |

Content |

|||||||||||||||||||||

|

A "Product Variant Rule" defines states and behavior of the Product Variant Status. A Product Variant Rule defines the statechart of a given Product Variant, including states, transitions, and how to invoke the Sampling Plan. All of this is determined based on the Batch History of Batches for the Product Variant. This Batch History looks at the date of the last Batch, how many Batches have passed since full testing was performed, and the final Disposition of the last Batch. Often, even for preferred Suppliers and Manufacturers, the system should require full testing of every nth Batch, or as an audit at the start of a year (or other time period). Typically, the Supplier or Manufacturer would be put on suspect watch if a Batch Disposition indicated that it failed testing.

A Product Variant Rule chooses a "Level" for a given "State":

| • | A "State" identifies the degree of confidence you have in items received from a Supplier and/or Manfacturer. All states are enumerated in the Product Variant Rule, including the important "Initial" state. |

| • | A "Level" indicates the degree of testing to be done on Batches received from a Supplier and/or Manfacturer. This is passed to the Sampling Plan to tell it which Samples and Tests are required. |

For each "State", a "Product Variant Rule" defines:

| • | A "Level Rule", which specifies when to apply the "Level" (such as "Set the 'Level to 'Reduced' for every 5th item in the Batch"). |

| • | A "Transition Rule", which defines transition to the next State (such as "Set the next 'State' to 'Qualified' when 5 items in the Batch have passed"). |

Shown above is the Product Variant Rule Maintenance page. The ProdVariant Rule States tab shows all states in the Product Variant state chart. For each state, the tab defines:

| • | "Level Rule" indicating how to invoke the Sampling Plan to drive what samples and testing is required. |

| • | "Transistion Rule" indicating when the Product Variant status transitions to a different status based on the Batch History. |

| • | "Initial State" to assign to the Product Variant. |

These buttons are provided:

| • | "Add" adds a new State. The states are taken from the Product Variant State Reference Type. |

| • | "Remove" removes a State. Make certain the state is not referenced from any Transistion Rule. If it is, an error will occur. |

Level Rules |

|

|

Level Rules specify a level of testing that depends on criteria such Batch count, Batch sequence, and number of Batches that have passed/failed within a time period (Split, Composite, Linked and Formulated Batches are not considered).

Level Rules are checked when a Batch is created or Received (as specified by the Sampling Plan Policy):

| 1. | The ApplySamplingPlan

Action gets the Product Variant record based on the Product and Supplier

and/or Manufaturer for the Batch, and then determines the Product Variant

Rule. This is best shown by example. Suppose the product has the following

Product Variants:

The principles behind these Product Variants are that when testing the RadialTire Product, we know that:

Based on the above, if ABC Labs supplies Dunlop tires, there are three Product Variant Rules that may qualify. The one chosen is based on the precedence defined in the Sampling Plan Policy. |

||||||||||||||||||||||||||||||||||||||

| 2. | This Action then tests each Level Rule in the Product Variant Rule until it finds one that passes, at which time it returns the corresponding Level. If none pass, the Action returns the Level from the "Otherwise" option. | ||||||||||||||||||||||||||||||||||||||

| 3. | The Level is used by the ApplySamplingPlan Action, along with the Sampling Plan defined for the Product Variant to create the samples. The SamplingPlan then works out the number of Samples, Sources from which they are taken, which the Tests are to be done on each. |

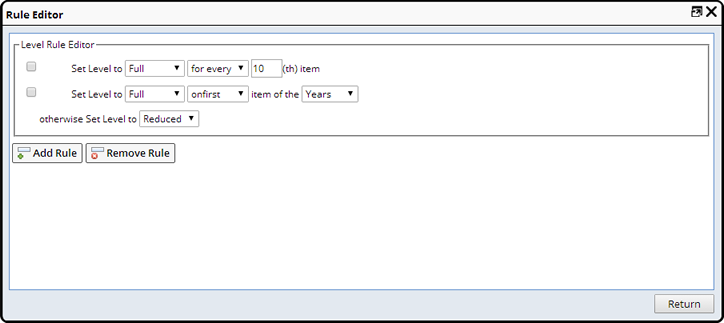

Clicking the ellipsis opens the Level Rule Editor:

This is where you define one or more rules that collectively define the Level Rule.

| • | "Add Rule" adds a rule. "Remove Rule" removes selected rules. |

| • | The Rule Editor uses dynamic dropdowns. After you set the Level, the choice you make from the remaining dropdowns determines and displays the relevant rule options. |

The following types of rules are provided to conditionally set Levels, i.e., these are the rules you can make using the dropdowns:

| 1. | Forcefully setting a Level:

Example: Set Level to Full always. |

| 2. | Choosing a Level for every nth Item:

Example: Set Level to Full for every 10th item. |

| 3. | Choosing a Level based on prior Batch Disposition:

Example: Set Level to Full when less than 2 items Failed Reduced within 10 Days. |

|||||||||||||||||||||||||||||||||

| 4. | Choosing a Level based on the start of a new time period:

Example: Set Level to Full on the first 3 items of the Quarter starting from the 1st month, otherwise Set Level to Full.

|

| 5. | Catch-all to choose a Level when one or more of the above returns

"false":

Example: Otherwise Set Level to Reduced. |

Transition Rules |

|

|

When a Batch is Released, a Transition Rule defines the "State" to which a Product Variant transitions.

Transition Rules depend on the number of Batches that have passed/failed within a time period (Split, Composite, Linked and Formulated Batches are not considered). You can set the state or leave it unchanged.

Transition Rules are checked when a Batch is Released:

| 1. | The EvalProdVariantState Action gets the Product Variant record from the Batch. The Product Variant then indicates the Product Variant Rule to use. |

| 2. | This Action then tests each Transition Rule in the Product Variant Rule until it finds one that passes, at which time it returns the corresponding state. If none pass, this implies that a transition is not required. |

| 3. | If Approval is not required, the returned State is set as the Current

State of the Product Variant. The Current State is then used to create

the next Batch.

If Approval is required, the State is set in the "Next State" column of the Product Variant, and the row is flagged for Approval. Meanwhile, until the Next State is Approved, newly created Batches continue to use the previous State. |

| 4. | After Approval is conducted, the Next State is copied into the Current State, then nulled. |

Transition Rules are governed by "Batch Disposition", not by Approval (they are coincidentally synchronized).

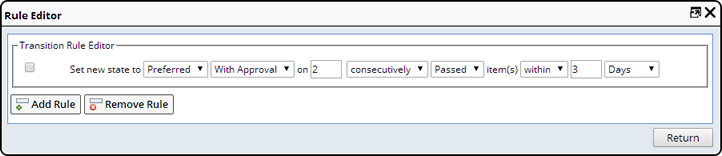

Clicking the ellipsis opens the Transition Rule Editor:

A typical Transition Rule could say "If one Batch failed, the new State will change to Unqualified".

The interface is similar to the Level Rule editor. One type of rule is provided:

|

|||||||||||||||||||||||||||||||||

Note that:

| • | "With Approval" means that the transition is not automatic; it requires manual Approval, which is done from the Product Variant List page or the "Approve" button on the Product Variant detail of the Product Maintenance page. |

| • | If you do not Approve a transition, you remain in the current state. You do not move backward to some type of "fail" state. |

| • | If the "consecutively" option is specified, Batches are required to be passed/failed consecutively in order to determine the state transition. In the example shown above, 2 consecutively passed Batches are required. Leave this blank if consecutive pass/fail is not required. |

Saving |

|

|

To save a Product Variant Rule, you must define one "Initial State". When a Product Variant is created and it specifies a Level Rule or Transition Rule, the "Current State" of the Product Variant is set to the "Initial State" specified here. In other words, this is the "start state".