|

Product Variants |

For a given "Product" and a combination of "Supplier"-"Manufacturer"-"Production Site", a "Product Variant" specifies:

| • | Current State of the Product Variant (defined by a Product Variant Rule "State") |

| • | Product Variant Rule |

| • | Sampling Plan |

These associations are made by column mapping in the Sampling Plan Policy, which matches the column values of the Batch SDI with the column values of the Product Variant SDI.

Product Variants let you define different rules for different Suppliers to different sources can have different Rules. For example, if a Product Variant is temporarily "Unqualified", you could use the Product Variant's "Current State" to switch between "Unqualified" and "Qualified". As another example, anytime a "Preferred" Supplier fails, you can switch back to "Unqualified". You can then see how State changes over time.

The ProductVariant SDC can be linked to any other SDC.

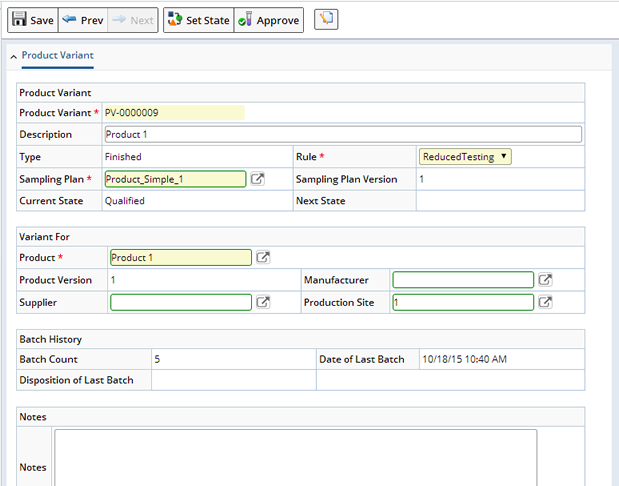

Product Variant Maintenance Page |

|

|

| Field | Description |

| Product Variant | Automatically generated KeyId1 of the Product Variant SDI. |

| Description | An optional textual description of this Product Variant. |

| Type | The Product Type of the parent Product (automatically populated). Can be either Raw Material or Finished. |

| Sampling Plan Sampling Plan Version |

Sampling Plan used for the Product Variant. |

| Rule | Product Variant Rule used by the Product Variant. |

| Product | Product on which the Samples in the Batch are based. |

| Current State | Current qualification of the "Product"

and a combination of "Supplier"-"Manufacturer"-"Production

Site". This is a measure of the degree of confidence you have in

the Supplier, and determines testing applied to an incoming Batch. See

Note 1.

This value is taken from the ProdVariantState Reference Type (Unqualified, Qualified, Preferred). |

| Supplier Manufacturer Production Site |

For a given Product, these collectively define

the source of the Samples in the Batch.

Note that "Supplier" and "Manufacturer" are actually an "Organization" SDI. If the Supplier and/or Manufacturer is left blank, the Product Variant applies to all Suppliers and/or Manufactures (respectively). Using these choices, you can treat Manufacturers and Suppliers separately, or you can have different variants based on combinations of Manufacturers and Suppliers. |

| Next State | State that will be set by the next transition. |

| Note 1: | When a Batch arrives, the ApplySamplingPlan

Action (called from the postAdd() SDC Rule of the Batch) performs

these operations:

|

Also see the example given in the Level

Rules section of the Product Variant

Rule document.

Associating Product Variants with Products |

|

|

You must associate one or more Product Variants with a Product. Do this in the Product Maintenance Page.