Overview |

|

|

Overview |

|

|

Batch Genealogy allows you to create new Batches by

| • | Splitting, combining or linking existing Batches from any Batch list page |

| • | Creating Formulated Batches for Products defined with a Formulation. |

You can then view the entire Genealogy of a Batch with the Genealogy Viewer. Once in the Genealogy Viewer you have several options for viewing and editing related Batches.

Creating New Batches with Genealogy |

|

|

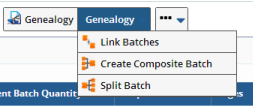

Create new Genealogy from existing Batches from any of these locations:

| LIMS | → | Batches | → | Active Batch List Batches Pending Release Historical Batches |

| Button | Description |

| Genealogy | View the entire Genealogy of the selected Batch using the Genealogy Viewer. |

| Link Batches | Creates a new linked Batch between two or more heterogeneous Batches. The new Batch is simply a link between the existing Batches, no Tests are added to the new Batch. |

| Create Composite Batch | Creates a new Composite Batch from existing homogeneous batches. You can optionally select a level, if not, no Sampling Plan will be used. |

| Split Batch | Splits an existing Batch into one or more new Batches. You can optionally select a Level, if not, no Sampling Plan will be used. Define the maximum number of Batches to be created by a split in BatchSamplePolicy. |

Link Batches |

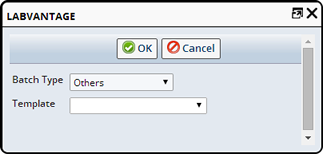

This allows you to create a link between two or more existing heterogeneous batches. Select two or more Batches in any Batch List page and click the "Link Batch" button. The Link Batch window opens where you can define the following options for the new batch:

| Link Batch Options | Choose... |

| Batch Type | Batch Type (as determined by the Batch Template, e.g., Raw Material or Finished). |

| Template | The Batch Template to use. |

Clicking the "Ok" button displays the Batch Maintenance Page where you can further define the new Batch. Samples are created based on the Product from the Parent Batches, however, no Tests are added to the new Batch. It is simply a link between Batches.

Note: When all of the selected Batches have the same Product, the Product information will default to the new batch. Otherwise the Product will be blank.

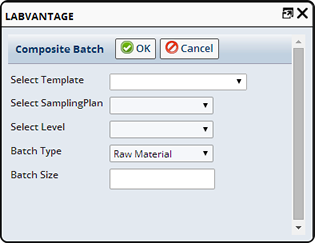

Create a Composite Batch |

Create a new Composite Batch from one or more existing homogeneous batches. Selecting one or more batch(es) in any Batch List and clicking the "Create Composite Batch" button opens the Composite Batch window where you can define the following for the new batch:

| Composite Batch Options | Choose... |

| Select Template | The Batch Template to use. |

| Select Sampling Plan | The Sampling Plan to use if a Level is selected. A sampling plan will not be used if no Level is selected. |

| Select Level | Optionally select a Level. If you select a Level the specified Sampling Plan will be used, no Sampling Plan will be used if a Level is not selected. |

| Batch Type | Batch Type (as determined by the Batch Template, e.g., Raw Material or Finished). |

| Batch Size | The size of the new batch. |

Clicking the "Ok" button opens the Batch Maintenance Page where you can further define the newly created batch.

Split Batch |

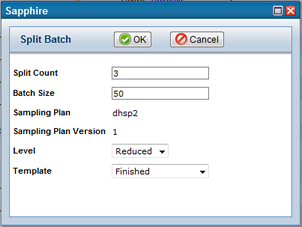

Using the Split Batch option you can create one or more new batches from an existing batch. Selecting a batch in any Batch List and clicking the "Split Batch" button opens the Split Batch window where you can define the following:

| Split Batch Options | Choose... |

| Split Count | The number of new Batches to create. The maximum number of Batches that can be created from a Split Batch is defined in BatchSamplePolicy |

| Batch Size | The size of the new Batch(es). |

| Sampling Plan | The Sampling Plan to use if a Level is selected. If no level is selected no Sampling Plan will be used. The Sampling Plan is defined by the original Batch. |

| Sampling Plan Version | The version of the Sampling Plan. |

| Level | Optionally select a level. If you select a level the specified Sampling Plan will be used, no Sampling Plan will be used if a level is not selected. |

| Template | The Batch Template to use. |

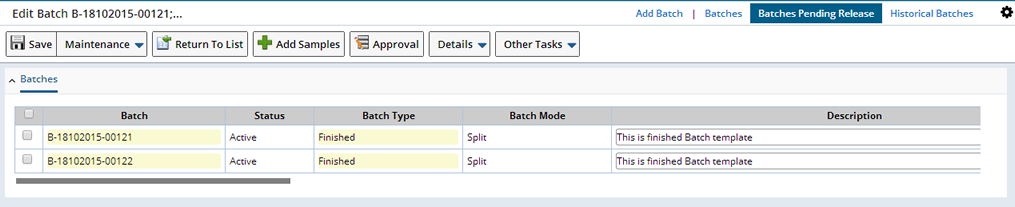

Clicking the "Ok" button creates three new Batches and displays them in the Batches tab of the Edit Batch window.

Scrolling right lets you edit Batch information for each Batch. See adding Batches on the Batch Maintenance Page for more information about each field. You then have the option to:

| • | Add Samples to each batch by selecting a Batch and clicking the "Add Samples" button. The Add Samples to Batch window displays. See Adding Samples to Existing Batches |

| • | Approve each Batch by selecting the Batch and clicking the "Approval" button. You can then Approve Tests and Specs for the Batch. |

Formulated Batch Genealogy |

|

|

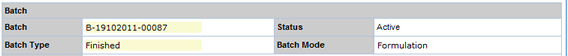

A Formulated Batch is created for Products with a formulation. The Formulation Module creates Formulation trial Batches for a Formulation Project. You can view and manage Formulation Batches here, however they are added from the Formulation Module.

Within Batch Management you can define a simple formulation consisting of multiple Products, combined to create one Product. A cake for example is made up of eggs, flour and sugar. A Cake Batch would then be made up of those three Products. The batch of cake would be the Formulated Batch with Batches of Eggs, Flour and Sugar as Parent Batches.

In order to create a Formulated Batch you must first create a Product with a formulation (a list of ingredients).

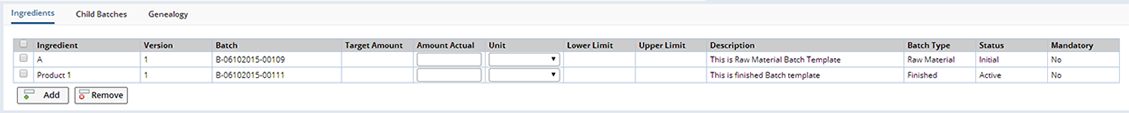

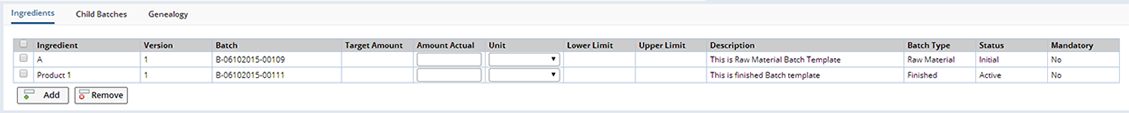

When you create and Save a Batch for that Product, a list of the related (Parent) Products displays in the Ingredients tab. Here you can Lookup and choose the Batch(es) you want to include (or associate) as Parent Batches for this Formulated Batch. These are the components of the Formulated Batch. Choose the Batch for each component Product you want to associate with this Formulated Batch.

| Field | Description |

| Product | The Product(s) to be included in the Formulation. |

| Batch | Lookup and select the related Parent Batch you want to include in this Formulated Batch. |

| Target Amount (Formulation Module) | Based on the Batch Size defined in a Formulation, this amount is calculated as a Target amount of this ingredient to use for the Batch. |

| Actual Amount (Formulation Module) | The Actual Amount to be used in the Batch. When Upper and Lower Limits are defined the Actual Amount must be within these limits. |

| Lower Limit (Formulation Module) | Defined within the Formulation Project, the Lower limit for Actual Amount used. |

| Upper Limit (Formulation Module) | Defined within the Formulation Project, the Upper limit for Actual Amount used. |

| Description | Batch Description. |

| Batch Type | Batch Type (as determined by the Batch Template, e.g., Raw Material or Finished). |

| Status | The Batch status. |

| Mandatory | Whether or not this is a Mandatory Parent Batch. Mandatory Parent Batches can not be Removed. This is determined when you add the Formulation to the Product. |

In the Batch Maintenance Page the Parent and Child Batches tabs display related Batches. Here you can Identify the related Parent Batches that will need to be released before the Formulated Batch can be released

Formulated Batch Release |

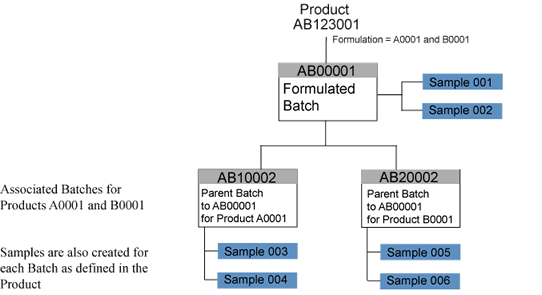

When releasing a Formulated Batch all Parent Batches that have been associated with the Formulated Batch as well as any associated Samples, as defined in the Product, are considered. Each of these Samples and Batches must be Released before the Formulated Batch can be Released.

In order to Release Batch AB00001 all Samples associated with both Parent Batches must be completed and the Parent Batches must be Released as well as any Samples associated with AB00001 itself.

Genealogy Viewer |

|

|

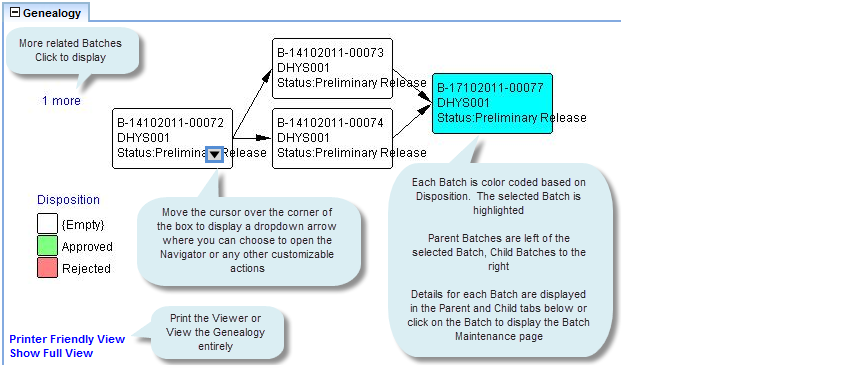

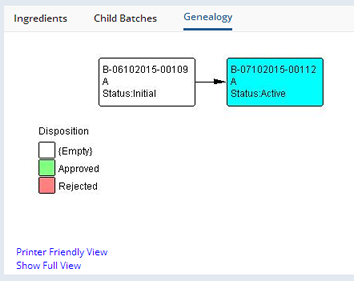

The Genealogy Viewer allows you to graphically view the entire Genealogy of a Batch. The viewer helps find a particular Batch in a manufacturing process. Access the viewer from any Batch List by selecting the Batch and clicking the "Genealogy" button or from the Batch Maintenance Page in the Genealogy tab.

Once in the viewer you have the following options:

| • | Click on any batch to display batch details |

| • | Choose an action from a user defined drop down menu to perform different activities or move to the Navigator |

| • | Print a printer friendly view of the Genealogy |

The Navigator is a Policy-driven feature that lets you view an entire Batch hierarchy as a tree of associated objects, then perform operations on them from within the tree view. This is an efficient alternative to using menus and tabs to access each object in a hierarchy. See Navigator Policy for more information about using the Navigator.

Viewing Genealogy From the Batch Maintenance Page |

On the Batch Maintenance Page you can view, add and remove related Parent Batches and view Child Batches.

From the Ingredients tab you can identify Parent Batches of Ingredients, Remove non mandatory Batches or add Batches that are not already in the hierarchy of the Batch and not rejected.

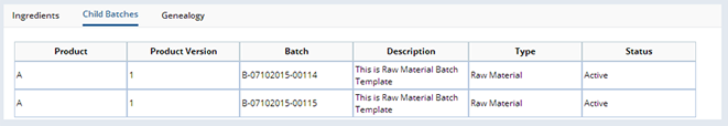

In the Child Batches tab you can view related Child Batches.

The Genealogy tab displays a graphical view of the Genealogy for this Batch.

Genealogy in List Pages |

When viewing Batches in list pages you can identify Batches with related Genealogy by these icons:

| Icon | Description |

|

|

Primary Batch, the original Batch that was used to create Linked, Split or Composite Batches. |

|

|

Linked Batch |

|

|

Composite Batch |

|

|

Split Batch |

|

|

Formulated Batch |

Configuring the Genealogy Viewer |

The Genealogy Viewer can be configured using The Web Page Designer in System Admin.

Using Genealogy with Versions Older than 5.1 |

|

|

The Batch Genealogy functions; Split, Composite, and Link Batches, require the Batch SDC to be keygenerated. Prior to R5.1, the OOB configuration was not configured with keygeneration on the Batch SDC, although it could be added. See SDC's, Key Generation for information about adding KeyGeneration.